Post by ChrisB on Jul 8, 2014 0:40:12 GMT

The Genexxa Pro LX5 speakers cost £70 apiece in Tandy, of all places and were interesting because they had the unusual tweeter design that had recently appeared on some very much more expensive speakers from a new American company called Linaeum. There was a bit of a buzz about them being rather special, not least due to coverage in HiFi News.

I bought my pair for use with a PC and they were fine for that purpose at the time - no fancy DAC's, just an old integrated amp being fed by an internal soundcard. Tried out on the big system for a short while, they sounded pretty good....but there were flaws. Mainly, there was not much bass at all - fairly expected, considering their tiny 5 litre cabinet size. What there was, however was really not that good at all because it boomed a bit and was rather tuneless.

Since then they've been used in makeshift systems in the garden, on holiday, for spells working away from home.......the list goes on. Then foam woofer surrounds gave up and they sat unused in the list of jobs to do.

During the interim though, I was thinking about how some of the other problems could be addressed. I've never messed about with speakers much, except for doing some basic rewiring and a recent driver refoaming, so I was a bit cautious about all this but I finally came up with a plan!

The Ingredients:

Tiny, cheap woofer

Cast aluminium cabinet with a thin wall

Plastic front baffle

Basic crossover built of basic components

Ropey wiring

Woofers

My thoughts were to first, and most obviously, repair the woofer surrounds - not too tricky as I had already tried my hand at this. They're tiny - the cones are about three and a half inches in diameter, so it surely wouldn't take long to do them! I considered changing them to different units and there's lots on the web about people who've done that but I didn't want to just blindly follow other peoples experiences, so thought I'd try and wring a bit more out of the original units and see where that got me first.

So new foam was ordered and I set about with the repair.

Woofer with new foam surround

Cabinet Bracing

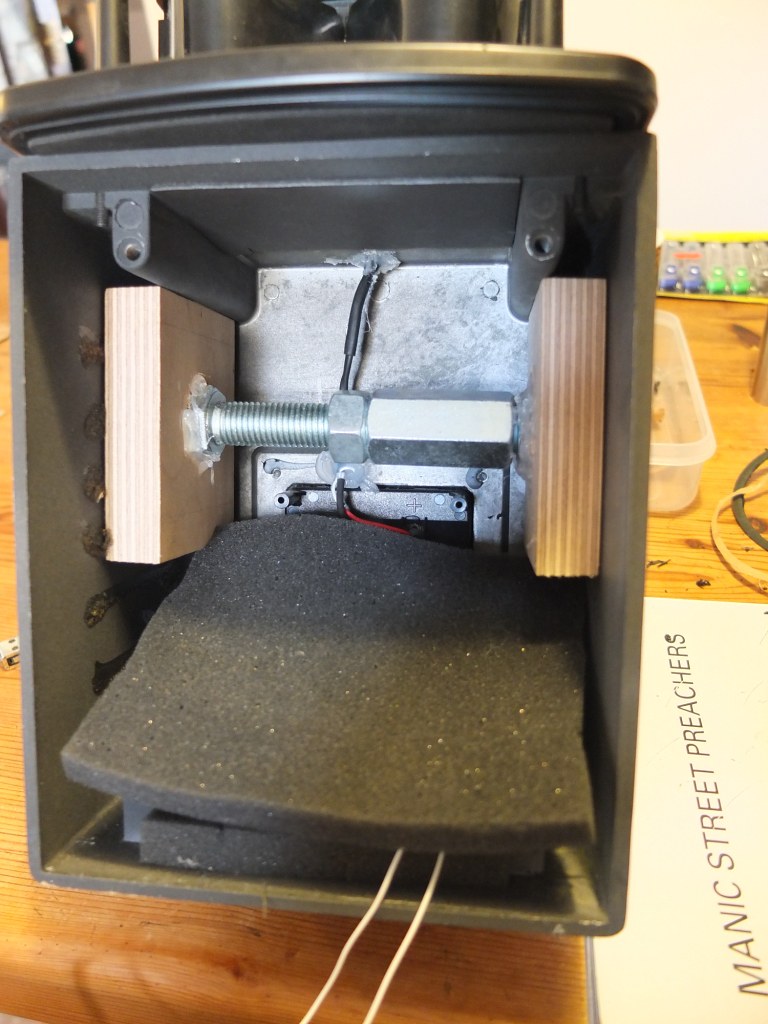

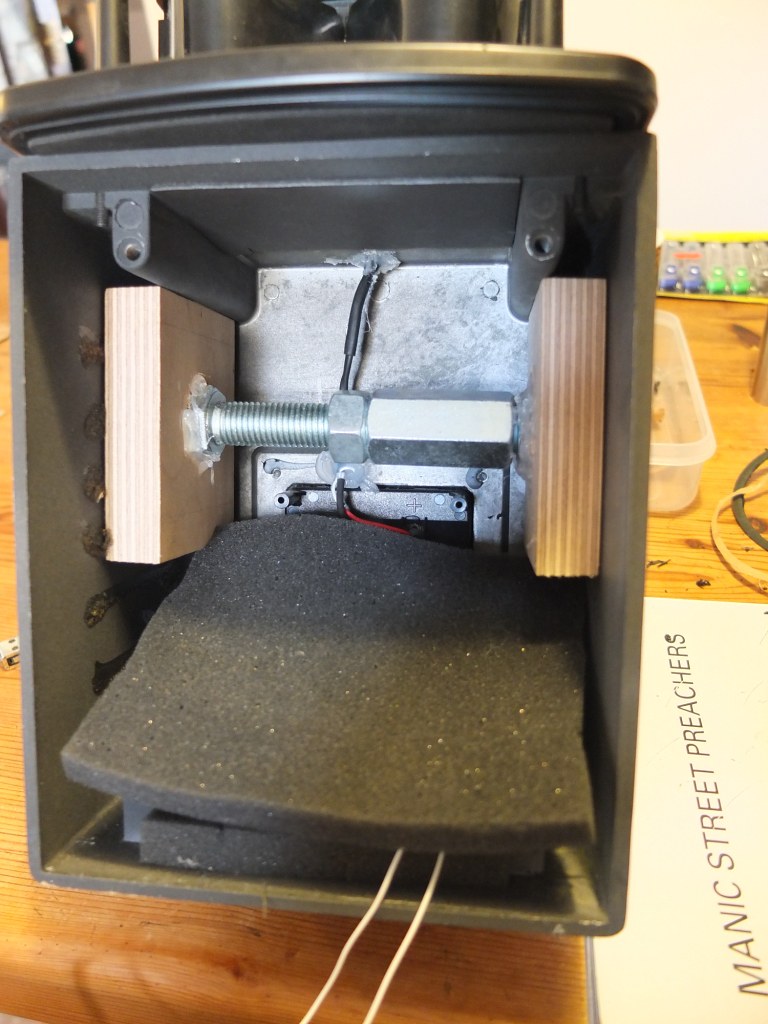

The cabinets must have been a source of some of that bass waffle, so I had to try to think of a way of applying some bracing to the side walls - they were vibrating quite a bit when the volume was turned up. I considered drilling holes and putting a threaded bar across from side to side and then tightening nuts on either end. I didn't really want to make holes in the cabinets in case tightening things up too far might crack them.

My solution was the opposite approach - to apply outward pressure to the walls from inside the cabinet by using a big (16mm diam) connecting nut with a bolt at each end and to crank it up tight in extension. There was a short bolt at one end, done up right into the connecting nut and a longer adjustable one at the other end - this was secured with a lock nut. The bolt heads sit in sockets that are drilled into squares of ply, which are in turn hot glued to the walls. The heads were then glued into the sockets.

The result? The walls are dead as a dodo - excellent! I also whacked a bit of Ded-Sheet on the inside of the top cabinet wall for good measure.

Cabinet bracing (note how thin the aluminium walls are)

Front Baffle

This is a bit flimsy so I thought it could do with a little help.

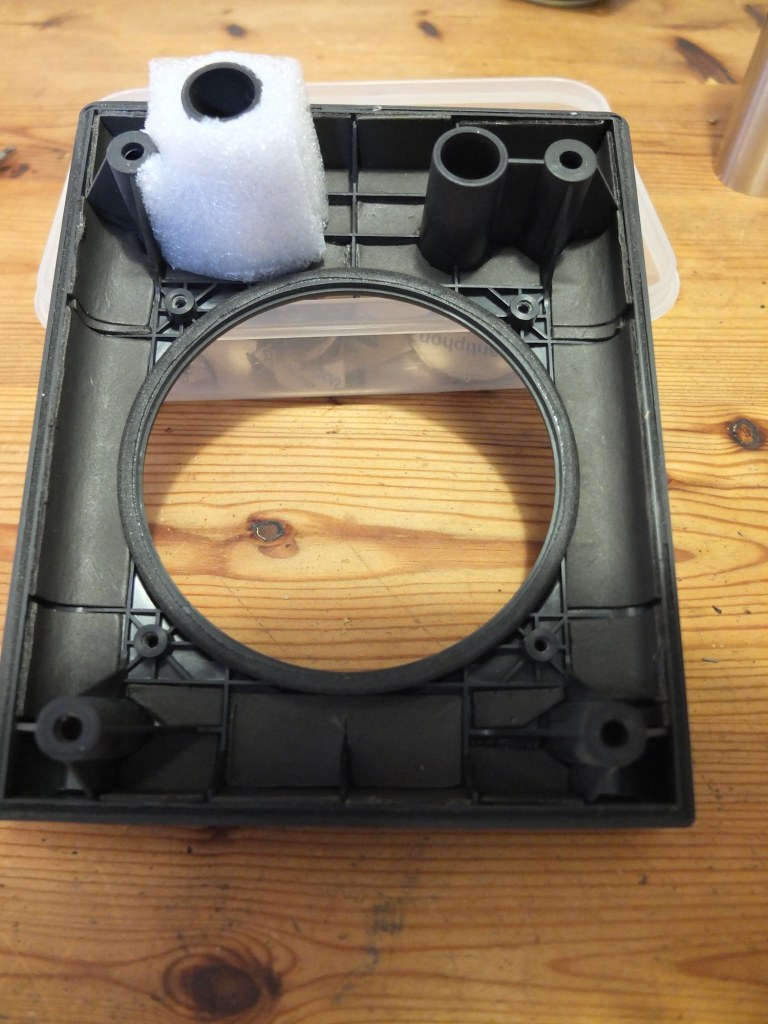

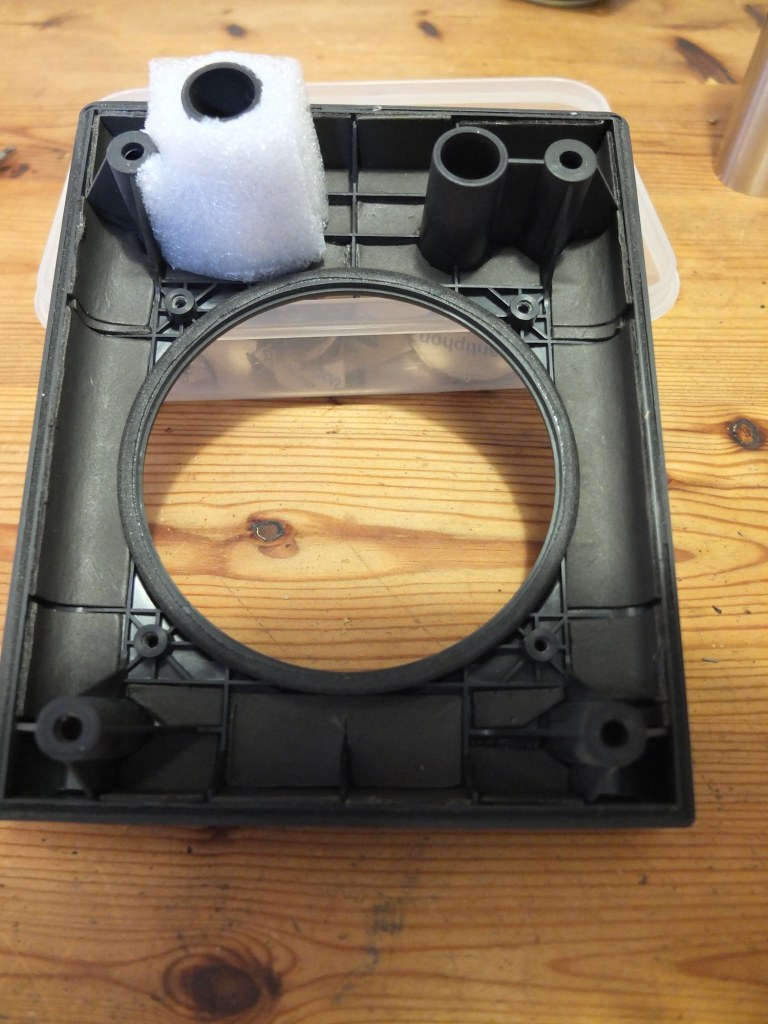

Baffle as standard - front

Baffle - Rear

The obvious thing to try was a bit of Ded-Sheet. Nice and cheap at under two quid a sheet - half a sheet did one baffle. This was a bit tiresome because of the manufacturer's attempt at bracing the baffle with many, many moulded ribs. Each section had to be made to measure and there weren't many that had their dimensions duplicated elsewhere on the baffle. I think it looks pretty tidy once finished. I also wanted to do something with the longer of the two reflex ports that are molded into the panel, so I made a sock for it out of some stiff expanded foam.

Finished front baffle

Crossover

I wanted several things from this part of the job:

Put some high quality components in there

Get it out of the cabinet but try to keep the speakers as portable as possible

Reconfigure it so that it can be bi-amped - I've been bi-amping for years and I am totally sold on its benefits

First off - I had a look at the wiring situation. Well, in for a penny, in for a pound - while I'm in there I may as well change that too. I had a problem though - the tweeter wires are fed through a hole in the top of the main cabinet and then do an immediate 90 degree turn to the solder terminals. The geometry and the fact that I didn't want to do any drilling in the aluminium, made it impossible to use my cable of choice, so I had to go with slim. I had some thin solid silver/ptfe stuff in my cables box, so that was used.

I bought some capacitors and good quality air cored inductors and put them into a cast aluminium box, to which I then applied the trusty old Ded-Sheet.

New Crossover Wired For Testing

Add some of that Dedsheet

The final part of the puzzle was to maintain the portability - I was able to keep it all reasonably compact by bolting the crossover box to the holes through which the old terminal plate was attached. I actually left the old plate in place with the old crossover components and sockets removed, as it was easier to seal that up than it would have been to get an effective seal between crossover box and cabinet. The old bolts were long enough to reach through to the threaded lugs in the cabinet.

No separate boxes, no extra connections and the speakers look just the same from the front (but a little pregnant from the side!) A lick of paint all round is required at some time.

Crossover Box Mounted

The Moment of Truth

After first checking everything with the meter, I made a quick test by connecting them up to an old (and expendable!) receiver - amazing, they work!

They went onto some good quality, heavy stands and were hooked up to the Mark Levinson power amps. They look a bit dwarfed by the normal speakers in this room!

Little and Large

Early results

All of the bass problems (apart from the depth, of course) had been addressed - the boom had gone. The definition was improved immeasurably. It's now possible to imagine that the bass player has an instrument with more than one string. There is a far more realistic 'snap' to everything.

The thing I didn't expect was what I now assume is the effect that the cabinet bracing has had on the tweeter. Before I did anything to the crossover or wiring, I played with the concept of the extending bolt and tried exerting a variety of pressures on the walls in order to prove my theory and it became obvious to me that by stopping the cabinet pumping and wobbling, the tweeter is now able to perform far far more convincingly. The difference that this has made is quite amazing - the image and soundstage are properly holographic and if you shut your eyes, the speakers themselves simply cease to exist. This aspect of reproduction is important to me and has informed the way my system has evolved over the years.

There was a slight channel imbalance but to say that I was chuffed with the result is a massive understatement.

Experiments with stuffing the ports and the cabinets

I removed the foam and wadding from the cabinets and MartinT very kindly sent me some lambswool that was left over from his Gale speaker project, I followed his suggestions and with some experimentation settled on a quantity of 19 grammes per speaker and reduced it because things seemed overdamped & I actually ended up with very much less.

Next, I did some experiments with stuffing the ports with straws and various different types of foam materials, from very open to very tight and dense. The effect I was getting was always detrimental - I assume the effectiveness of the bracing method that I used did all the work of reducing boom and waffle. I don't think I was imagining that the velocity and power of the blasts of air that emerge from those tiny ports seemed to have increased significantly. This implies to me that the bass driver is starting and stopping very quickly indeed.

Clusters of drinking straws were tried and rejected because I couldn't stop them from making their own noise. I think this is because the diameter of the ports is so small and the volumes I like to play at mean that the pressure through them is extremely high. They sounded just like something hard touching the bass cone as it plays staccato rhythms. I tried all sorts of methods of using them until I realised that they weren't bringing anything to the party anyway. A shame, as I found some nice black straws that you couldn't see!

There was still that slight channel imbalance, though it didn't seem nearly as prominent as before for some reason. Juiced up with the Radford STA 15, they sounded great, but they really leapt into life when they got the bi-amped Levinson power amps treatment. I have heard plenty of pairs of small monitors over the years but I've never EVER heard any that were so able to fill a room with such a massive sound. And they completely disappear - the music is just there, hanging in the air and the imaging is phenomenal. They're stood next to the massive Mirage M3si's and, you'd be forgiven for not knowing which speakers were playing. It's only the lack of deep bass that makes you realise it's those teeny little pipsqueaks at work.

Amazing.....just amazing.

Replacement Tweeters

Another pair of LX5s were procured as tweeter donors once the reason for the channel imbalance was isolated.

When I found the time to get the donor speakers checked over & I popped the top off the first tweeter, I couldn't believe the quantity of dust that was there. It had formed a thick mat on the top section of the unit.

Replacement tweeter after spending about 10 minutes cleaning it.

Then, after a lot more work.....shiny!

More Wiring Changes

I devised a way of using my normal speaker cable from amp to drivers. The original reason for using thin cable was because the original cable goes up through a small hole in the top of the cabinet and from there, it is attached to the tweeter tags. I didn't want to drill the cabinets to make this hole bigger, so I stuck with weeny wire. My solution was to bring the tweeter feed up from my crossover box (which is externally mounted on the back of the speaker, remember), outside the cabinet & straight to the tweeter. I also took the opportunity to directly solder all the connections that had been made with spade terminals in the standard design and I sealed the original cable hole with hot melt glue and a blanking plate.

With the tweeter swap the balance was restored nicely as far as is possible to tell with the ears available to me! With the preamp set to mono and the speakers sat right beside each other, swinging the balance from left to right demonstrates no perceptible differences, so all appears to be good.

A final picture of the new external wiring arrangement and how I trimmed the grilles so it all fits neatly together. The grilles come off for serious listening.

There it is then, I learnt a lot, had some great fun and repaired and improved a much loved pair of speakers.

The original model name of these speakers was Genexxa Pro LX5, but due to the modifications and the fact that the new crossover enclosure hangs out the back like that it was obvious that a new designation was required so they've been renamed the 'Pro(lapse) LX5'

I bought my pair for use with a PC and they were fine for that purpose at the time - no fancy DAC's, just an old integrated amp being fed by an internal soundcard. Tried out on the big system for a short while, they sounded pretty good....but there were flaws. Mainly, there was not much bass at all - fairly expected, considering their tiny 5 litre cabinet size. What there was, however was really not that good at all because it boomed a bit and was rather tuneless.

Since then they've been used in makeshift systems in the garden, on holiday, for spells working away from home.......the list goes on. Then foam woofer surrounds gave up and they sat unused in the list of jobs to do.

During the interim though, I was thinking about how some of the other problems could be addressed. I've never messed about with speakers much, except for doing some basic rewiring and a recent driver refoaming, so I was a bit cautious about all this but I finally came up with a plan!

The Ingredients:

Tiny, cheap woofer

Cast aluminium cabinet with a thin wall

Plastic front baffle

Basic crossover built of basic components

Ropey wiring

Woofers

My thoughts were to first, and most obviously, repair the woofer surrounds - not too tricky as I had already tried my hand at this. They're tiny - the cones are about three and a half inches in diameter, so it surely wouldn't take long to do them! I considered changing them to different units and there's lots on the web about people who've done that but I didn't want to just blindly follow other peoples experiences, so thought I'd try and wring a bit more out of the original units and see where that got me first.

So new foam was ordered and I set about with the repair.

Woofer with new foam surround

Cabinet Bracing

The cabinets must have been a source of some of that bass waffle, so I had to try to think of a way of applying some bracing to the side walls - they were vibrating quite a bit when the volume was turned up. I considered drilling holes and putting a threaded bar across from side to side and then tightening nuts on either end. I didn't really want to make holes in the cabinets in case tightening things up too far might crack them.

My solution was the opposite approach - to apply outward pressure to the walls from inside the cabinet by using a big (16mm diam) connecting nut with a bolt at each end and to crank it up tight in extension. There was a short bolt at one end, done up right into the connecting nut and a longer adjustable one at the other end - this was secured with a lock nut. The bolt heads sit in sockets that are drilled into squares of ply, which are in turn hot glued to the walls. The heads were then glued into the sockets.

The result? The walls are dead as a dodo - excellent! I also whacked a bit of Ded-Sheet on the inside of the top cabinet wall for good measure.

Cabinet bracing (note how thin the aluminium walls are)

Front Baffle

This is a bit flimsy so I thought it could do with a little help.

Baffle as standard - front

Baffle - Rear

The obvious thing to try was a bit of Ded-Sheet. Nice and cheap at under two quid a sheet - half a sheet did one baffle. This was a bit tiresome because of the manufacturer's attempt at bracing the baffle with many, many moulded ribs. Each section had to be made to measure and there weren't many that had their dimensions duplicated elsewhere on the baffle. I think it looks pretty tidy once finished. I also wanted to do something with the longer of the two reflex ports that are molded into the panel, so I made a sock for it out of some stiff expanded foam.

Finished front baffle

Crossover

I wanted several things from this part of the job:

Put some high quality components in there

Get it out of the cabinet but try to keep the speakers as portable as possible

Reconfigure it so that it can be bi-amped - I've been bi-amping for years and I am totally sold on its benefits

First off - I had a look at the wiring situation. Well, in for a penny, in for a pound - while I'm in there I may as well change that too. I had a problem though - the tweeter wires are fed through a hole in the top of the main cabinet and then do an immediate 90 degree turn to the solder terminals. The geometry and the fact that I didn't want to do any drilling in the aluminium, made it impossible to use my cable of choice, so I had to go with slim. I had some thin solid silver/ptfe stuff in my cables box, so that was used.

I bought some capacitors and good quality air cored inductors and put them into a cast aluminium box, to which I then applied the trusty old Ded-Sheet.

New Crossover Wired For Testing

Add some of that Dedsheet

The final part of the puzzle was to maintain the portability - I was able to keep it all reasonably compact by bolting the crossover box to the holes through which the old terminal plate was attached. I actually left the old plate in place with the old crossover components and sockets removed, as it was easier to seal that up than it would have been to get an effective seal between crossover box and cabinet. The old bolts were long enough to reach through to the threaded lugs in the cabinet.

No separate boxes, no extra connections and the speakers look just the same from the front (but a little pregnant from the side!) A lick of paint all round is required at some time.

Crossover Box Mounted

The Moment of Truth

After first checking everything with the meter, I made a quick test by connecting them up to an old (and expendable!) receiver - amazing, they work!

They went onto some good quality, heavy stands and were hooked up to the Mark Levinson power amps. They look a bit dwarfed by the normal speakers in this room!

Little and Large

Early results

All of the bass problems (apart from the depth, of course) had been addressed - the boom had gone. The definition was improved immeasurably. It's now possible to imagine that the bass player has an instrument with more than one string. There is a far more realistic 'snap' to everything.

The thing I didn't expect was what I now assume is the effect that the cabinet bracing has had on the tweeter. Before I did anything to the crossover or wiring, I played with the concept of the extending bolt and tried exerting a variety of pressures on the walls in order to prove my theory and it became obvious to me that by stopping the cabinet pumping and wobbling, the tweeter is now able to perform far far more convincingly. The difference that this has made is quite amazing - the image and soundstage are properly holographic and if you shut your eyes, the speakers themselves simply cease to exist. This aspect of reproduction is important to me and has informed the way my system has evolved over the years.

There was a slight channel imbalance but to say that I was chuffed with the result is a massive understatement.

Experiments with stuffing the ports and the cabinets

I removed the foam and wadding from the cabinets and MartinT very kindly sent me some lambswool that was left over from his Gale speaker project, I followed his suggestions and with some experimentation settled on a quantity of 19 grammes per speaker and reduced it because things seemed overdamped & I actually ended up with very much less.

Next, I did some experiments with stuffing the ports with straws and various different types of foam materials, from very open to very tight and dense. The effect I was getting was always detrimental - I assume the effectiveness of the bracing method that I used did all the work of reducing boom and waffle. I don't think I was imagining that the velocity and power of the blasts of air that emerge from those tiny ports seemed to have increased significantly. This implies to me that the bass driver is starting and stopping very quickly indeed.

Clusters of drinking straws were tried and rejected because I couldn't stop them from making their own noise. I think this is because the diameter of the ports is so small and the volumes I like to play at mean that the pressure through them is extremely high. They sounded just like something hard touching the bass cone as it plays staccato rhythms. I tried all sorts of methods of using them until I realised that they weren't bringing anything to the party anyway. A shame, as I found some nice black straws that you couldn't see!

There was still that slight channel imbalance, though it didn't seem nearly as prominent as before for some reason. Juiced up with the Radford STA 15, they sounded great, but they really leapt into life when they got the bi-amped Levinson power amps treatment. I have heard plenty of pairs of small monitors over the years but I've never EVER heard any that were so able to fill a room with such a massive sound. And they completely disappear - the music is just there, hanging in the air and the imaging is phenomenal. They're stood next to the massive Mirage M3si's and, you'd be forgiven for not knowing which speakers were playing. It's only the lack of deep bass that makes you realise it's those teeny little pipsqueaks at work.

Amazing.....just amazing.

Replacement Tweeters

Another pair of LX5s were procured as tweeter donors once the reason for the channel imbalance was isolated.

When I found the time to get the donor speakers checked over & I popped the top off the first tweeter, I couldn't believe the quantity of dust that was there. It had formed a thick mat on the top section of the unit.

Replacement tweeter after spending about 10 minutes cleaning it.

Then, after a lot more work.....shiny!

More Wiring Changes

I devised a way of using my normal speaker cable from amp to drivers. The original reason for using thin cable was because the original cable goes up through a small hole in the top of the cabinet and from there, it is attached to the tweeter tags. I didn't want to drill the cabinets to make this hole bigger, so I stuck with weeny wire. My solution was to bring the tweeter feed up from my crossover box (which is externally mounted on the back of the speaker, remember), outside the cabinet & straight to the tweeter. I also took the opportunity to directly solder all the connections that had been made with spade terminals in the standard design and I sealed the original cable hole with hot melt glue and a blanking plate.

With the tweeter swap the balance was restored nicely as far as is possible to tell with the ears available to me! With the preamp set to mono and the speakers sat right beside each other, swinging the balance from left to right demonstrates no perceptible differences, so all appears to be good.

A final picture of the new external wiring arrangement and how I trimmed the grilles so it all fits neatly together. The grilles come off for serious listening.

There it is then, I learnt a lot, had some great fun and repaired and improved a much loved pair of speakers.

The original model name of these speakers was Genexxa Pro LX5, but due to the modifications and the fact that the new crossover enclosure hangs out the back like that it was obvious that a new designation was required so they've been renamed the 'Pro(lapse) LX5'