Post by zappytheviking on Sept 14, 2017 22:40:40 GMT

Summer and power tools makes time fly.

Building your own without auditioning is a gamble, yet the promise is value for money and satisfaction in making something.

Why these specifically, high sensitivity +91db, 8ohm and a reasonable price, will be able to use class-A or tubes without needing monster amps.

Here are more details for the interested. www.troelsgravesen.dk/SEAS-3-Way-Classic-mkII.htm

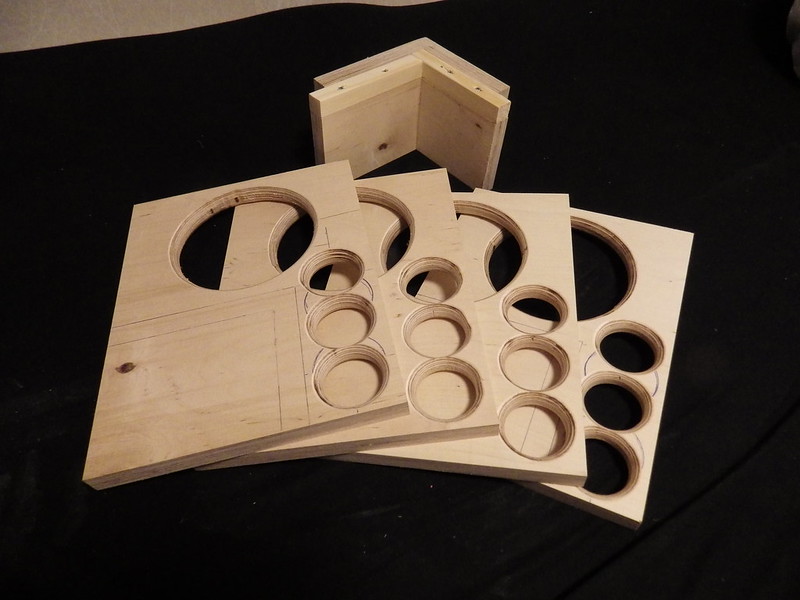

It all started with a pile of wood, 21mm birch ply, solid as a rock and heavy as sin.

Glue and screws for the poor in clamps.

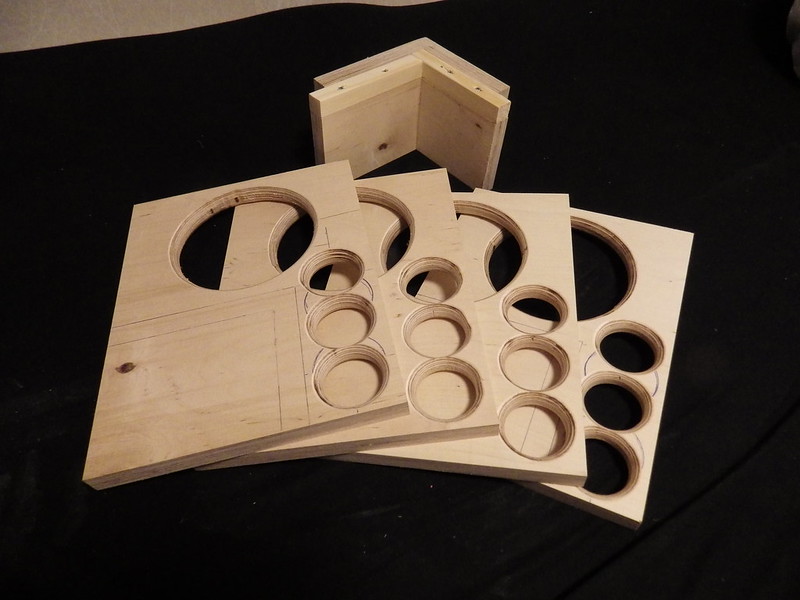

Mid range shelves with accompanying blowholes.

Some more stabilization for the lower section, only slightly wobbly circles.

Starting to glue in the assorted pieces one by one.

A speaker stand might be good to have, random leftover wood found and shaped.

Some time later, a lick of paint and 12kg of oven dried sand from the yard.

An early look at the semi finished speaker with measurements drawn on the wood.

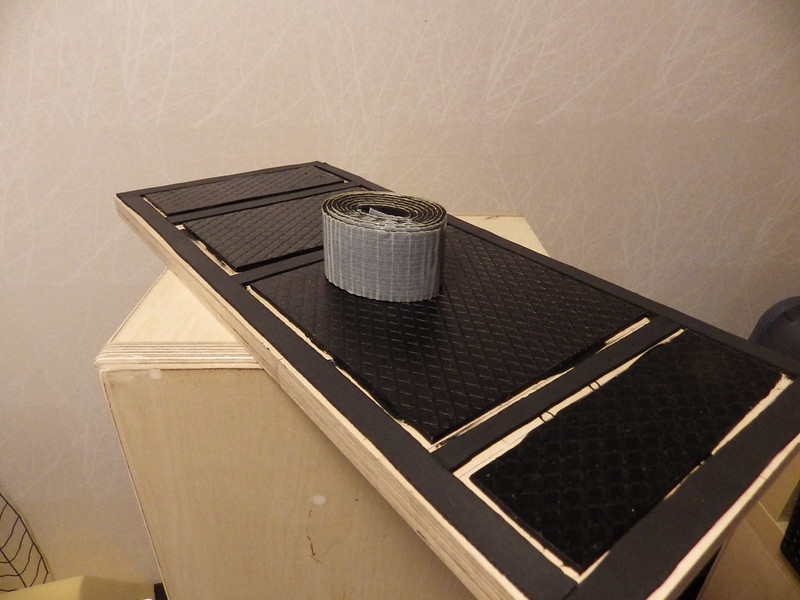

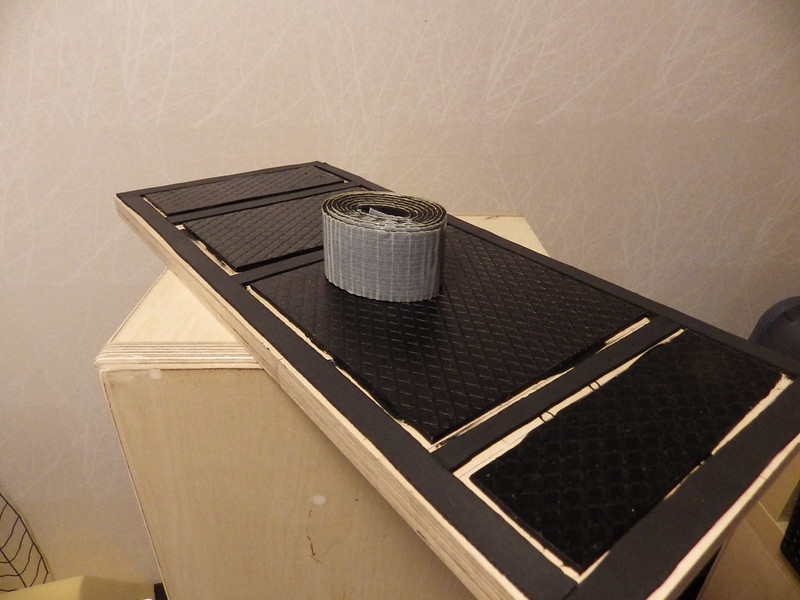

Gluing in 4mm bitumen pads with some rather black and sticky building goop, Mass loading and vibration dampening, speaker is starting to get heavy, my poor back.

The back will be fastened with a large handful of screws, this air-cond foam strip does a lovely job at making an air tight seal.

Further damping with cloth stuff included in speaker kit. Hot melt glue worked really well.

Another day of sanding, rounding and shaping.

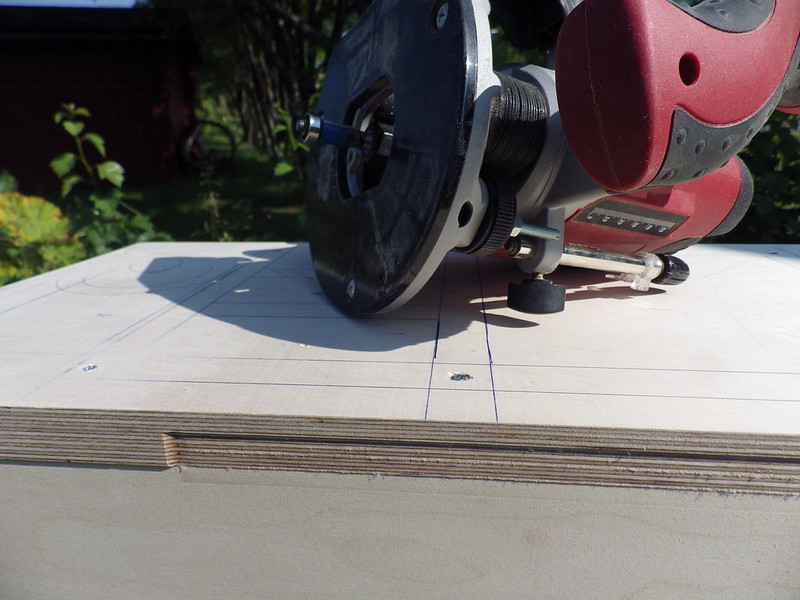

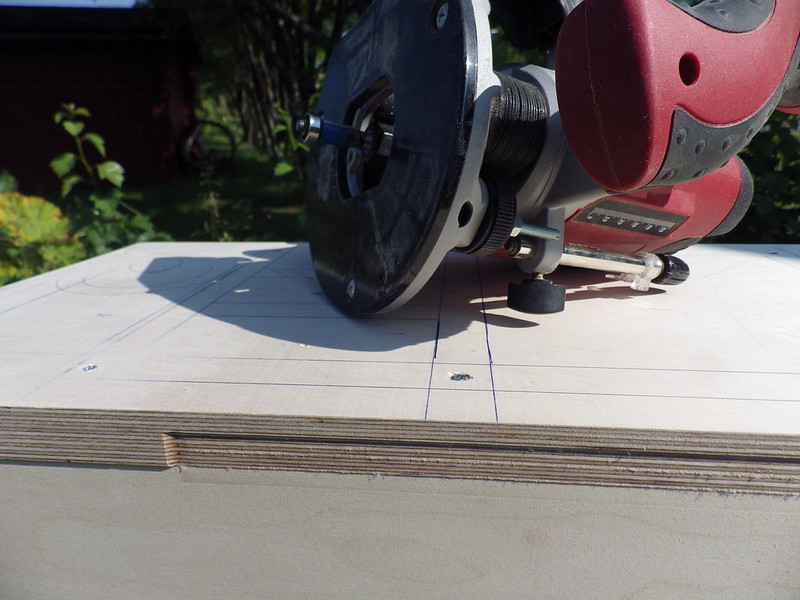

Leveling the panels with a router, so handy and fast, just make sure you have some spare bearings for the bit, they tend to fly off.

First layers of primer, I really should have kept sanding, you can never have too perfect a foundation before paint. In hindsight, I should have used some form of sealer on the wood first.

Next time I will try car body repair putty and sealing that with epoxy, used some regular wood filler, gave me plenty of trouble later by poking thru the finish.

Wind gusts making my expensive 2K spray paint fly away and into my eyes, unexpected rain, flies landing on ooh so shiny a surface, must be water right. I finally built a ventilated indoor spray booth

After 4 layers of black and 5 layers of laquer with occasional sanding between layers, a bit better.

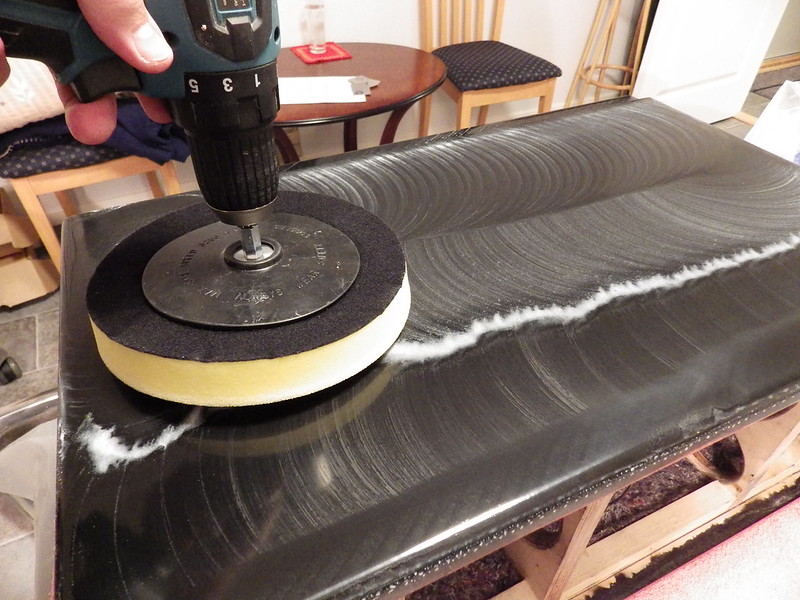

Some wet sanding, 800-1200-2000.

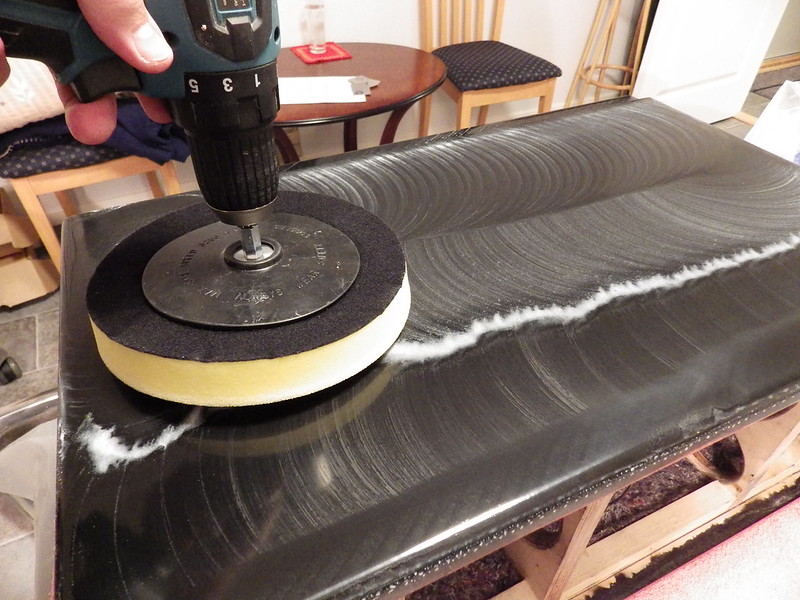

A bit of cutting compound and finishing off with car wax.

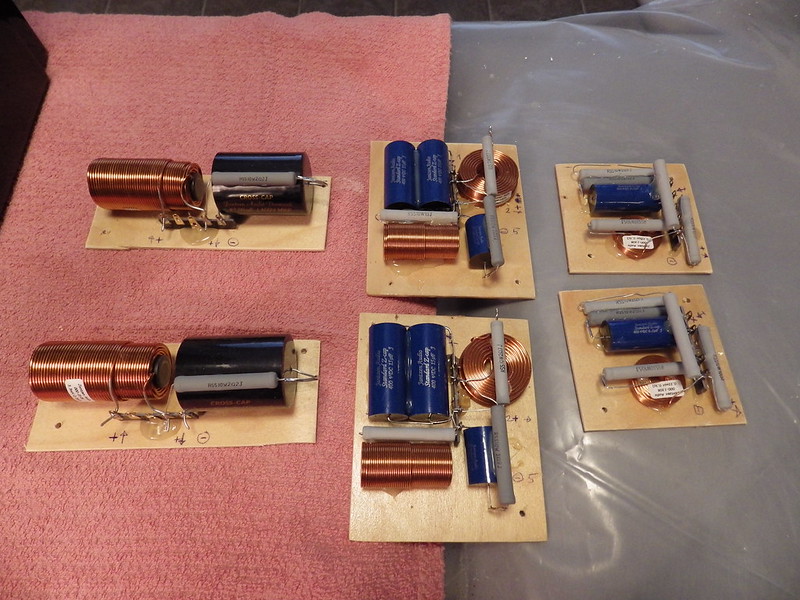

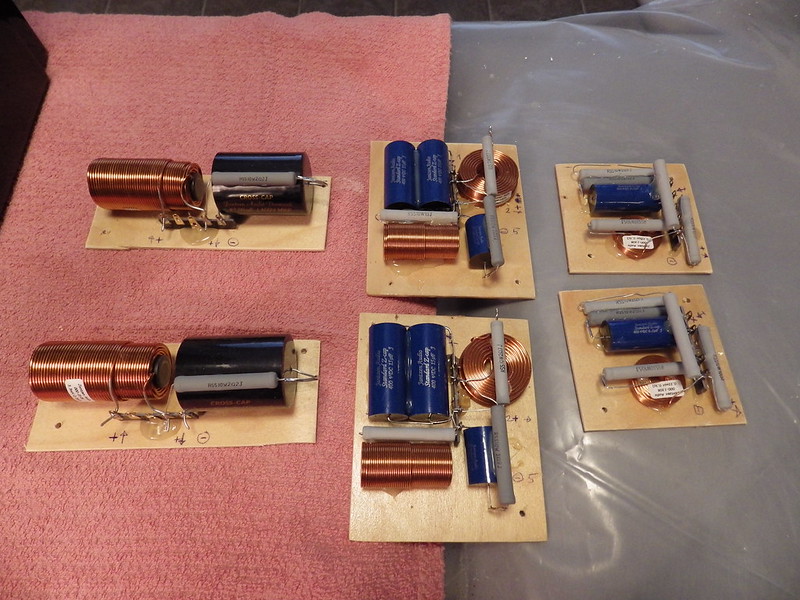

Before the grand finale, the crossovers, made them all separate, better for bi/tri wire some day in the future.

Well, here we are, a functioning speaker, the finish is still not where I would like it but after 2 months of hard work it will have to wait, perhaps next summer.

A lesson learned for a high gloss finish, use a cheaper acrylic lacquer for the base coats, finish off with the 5-10x more expensive 2K for a hard surface.

Oh and avoid corners when machine polishing, it will rip the finish right off.

What do they sound like?

Well, firstly consider I am using an ancient entry level amp, it does muffle things up a bit.

They are heavy beasts, will weight them later, as a guess 35kg a piece. Having a hard time saying exactly what this speaker sounds like. What strikes me most is the clean mid range and bass.

I do not lack for a subwoofer, it fills the room quite well.

A thought that came to me when I first heard them, somehow I expected a good speaker to be bombastic and dynamic. Boy was I wrong, quality in this case is a large and effortless sound, well balanced.

I was expecting a monster truck, preconceived bias haha, I got a Steinway grand piano, not complaining.

Is it a good speaker? well yes, I will attempt a write up later on when I have proper amplification.

To anyone building these, they open up remarkably after 2 weeks, was not happy at first, burn in time is real .

.

Next upgrade is a fitting amplifier and later on a DAC-pre, perhaps the AUDIO-GD NFB-28.28.

If there are questions do ask and I will try to respond

Building your own without auditioning is a gamble, yet the promise is value for money and satisfaction in making something.

Why these specifically, high sensitivity +91db, 8ohm and a reasonable price, will be able to use class-A or tubes without needing monster amps.

Here are more details for the interested. www.troelsgravesen.dk/SEAS-3-Way-Classic-mkII.htm

It all started with a pile of wood, 21mm birch ply, solid as a rock and heavy as sin.

Glue and screws for the poor in clamps.

Mid range shelves with accompanying blowholes.

Some more stabilization for the lower section, only slightly wobbly circles.

Starting to glue in the assorted pieces one by one.

A speaker stand might be good to have, random leftover wood found and shaped.

Some time later, a lick of paint and 12kg of oven dried sand from the yard.

An early look at the semi finished speaker with measurements drawn on the wood.

Gluing in 4mm bitumen pads with some rather black and sticky building goop, Mass loading and vibration dampening, speaker is starting to get heavy, my poor back.

The back will be fastened with a large handful of screws, this air-cond foam strip does a lovely job at making an air tight seal.

Further damping with cloth stuff included in speaker kit. Hot melt glue worked really well.

Another day of sanding, rounding and shaping.

Leveling the panels with a router, so handy and fast, just make sure you have some spare bearings for the bit, they tend to fly off.

First layers of primer, I really should have kept sanding, you can never have too perfect a foundation before paint. In hindsight, I should have used some form of sealer on the wood first.

Next time I will try car body repair putty and sealing that with epoxy, used some regular wood filler, gave me plenty of trouble later by poking thru the finish.

Wind gusts making my expensive 2K spray paint fly away and into my eyes, unexpected rain, flies landing on ooh so shiny a surface, must be water right. I finally built a ventilated indoor spray booth

After 4 layers of black and 5 layers of laquer with occasional sanding between layers, a bit better.

Some wet sanding, 800-1200-2000.

A bit of cutting compound and finishing off with car wax.

Before the grand finale, the crossovers, made them all separate, better for bi/tri wire some day in the future.

Well, here we are, a functioning speaker, the finish is still not where I would like it but after 2 months of hard work it will have to wait, perhaps next summer.

A lesson learned for a high gloss finish, use a cheaper acrylic lacquer for the base coats, finish off with the 5-10x more expensive 2K for a hard surface.

Oh and avoid corners when machine polishing, it will rip the finish right off.

What do they sound like?

Well, firstly consider I am using an ancient entry level amp, it does muffle things up a bit.

They are heavy beasts, will weight them later, as a guess 35kg a piece. Having a hard time saying exactly what this speaker sounds like. What strikes me most is the clean mid range and bass.

I do not lack for a subwoofer, it fills the room quite well.

A thought that came to me when I first heard them, somehow I expected a good speaker to be bombastic and dynamic. Boy was I wrong, quality in this case is a large and effortless sound, well balanced.

I was expecting a monster truck, preconceived bias haha, I got a Steinway grand piano, not complaining.

Is it a good speaker? well yes, I will attempt a write up later on when I have proper amplification.

To anyone building these, they open up remarkably after 2 weeks, was not happy at first, burn in time is real

.

.Next upgrade is a fitting amplifier and later on a DAC-pre, perhaps the AUDIO-GD NFB-28.28.

If there are questions do ask and I will try to respond

.

.